Inner Excellence. True Music. Since 1985.

Music moves us – as engineers, as musicians, and as people. For 40 years, we at Mundorf have dedicated ourselves to the quality of sound, exploring through research and development how material properties, design and acoustic performance are interconnected – always with the goal of unlocking the very best from every component. Our components free music from distortion, giving it depth, structure and character. They form the silent foundation of an emotional listening experience. Inner Excellence is our contribution as a trusted partner to the audio industry – True Music is the result.

Discover our story, our product and application portfolio, and the technologies that bring this idea to life.

1985

Founded in Cologne

40

Years of Inner Excellence

30

Employees in Cologne

10+

International patents

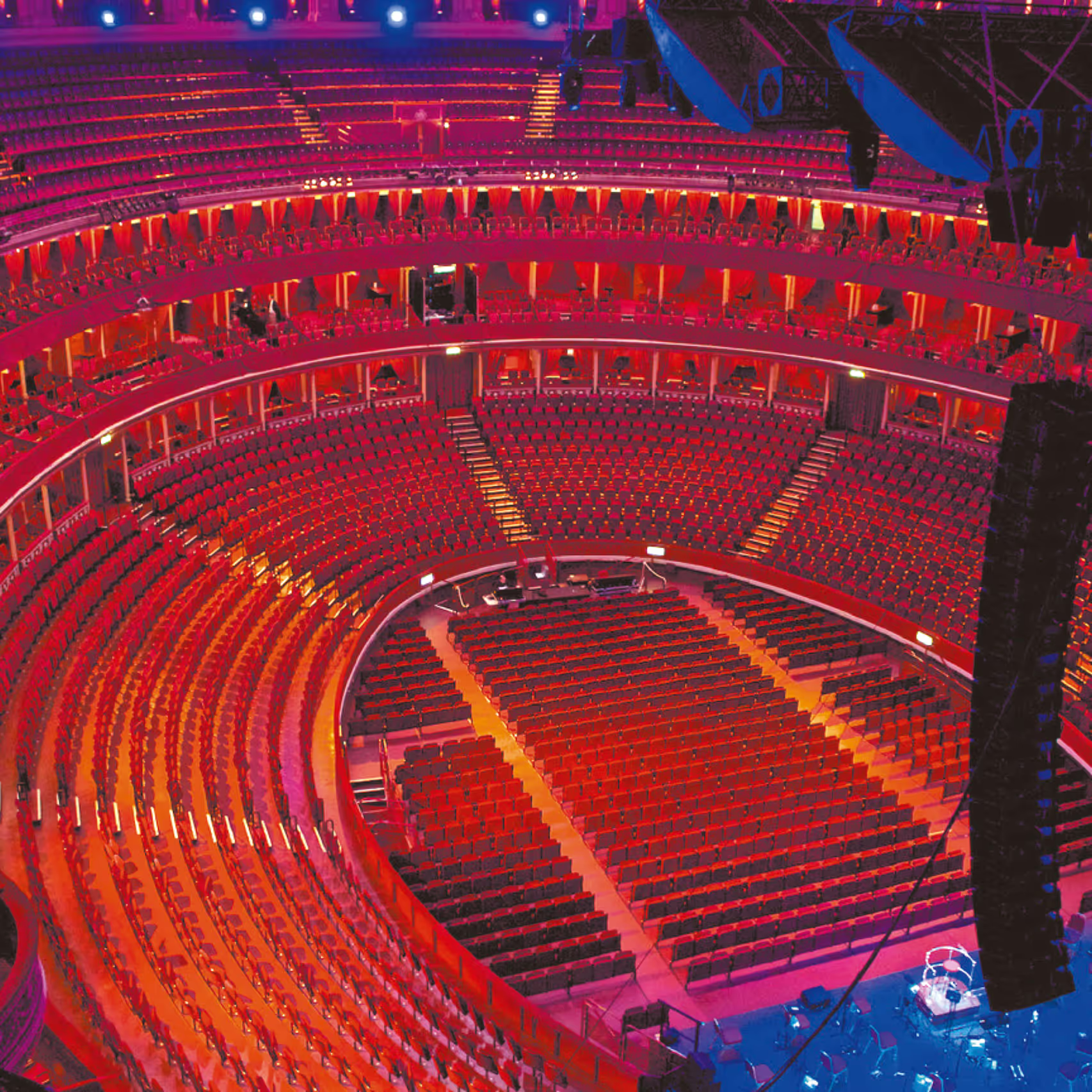

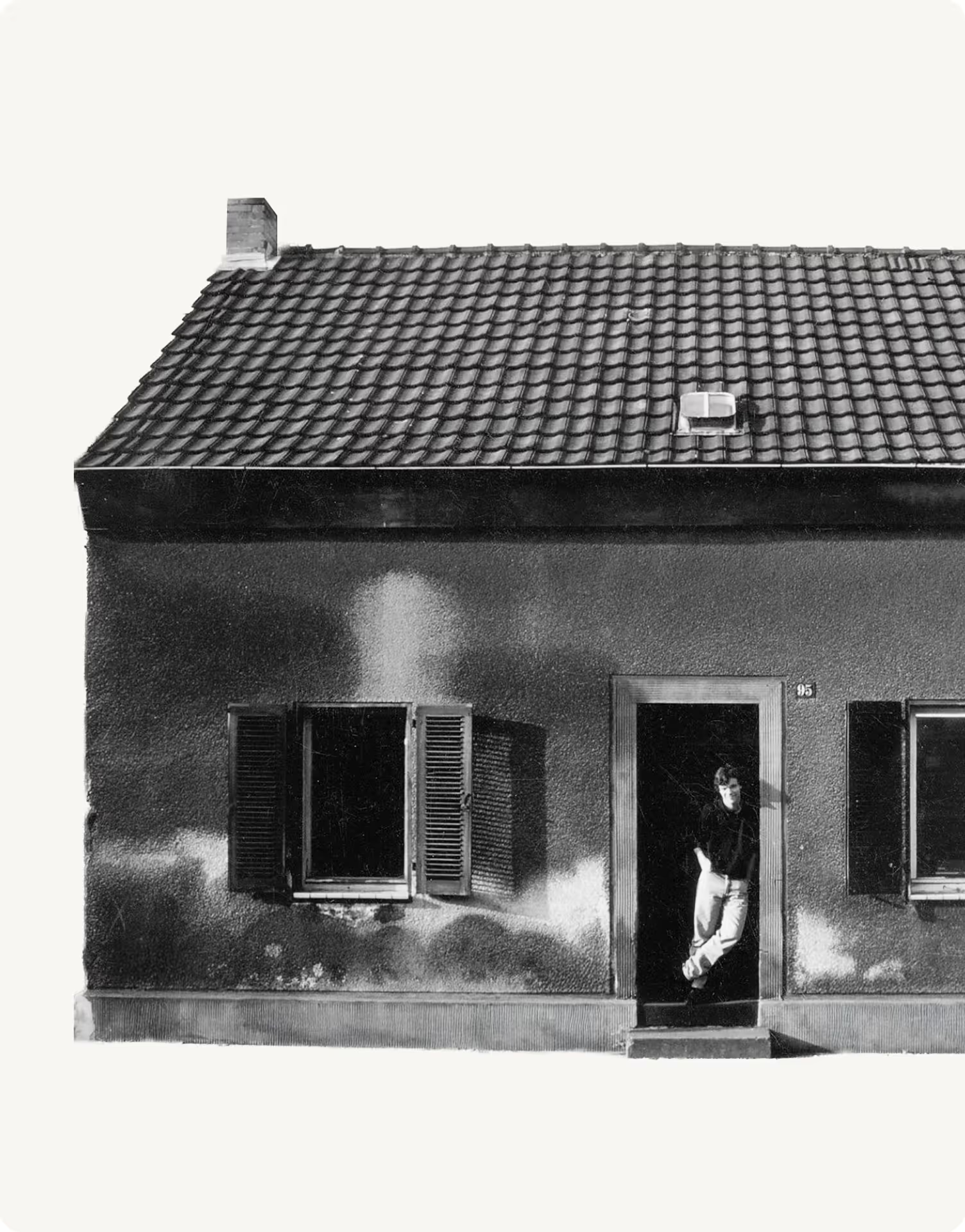

From Living Room to Royal Albert Hall

Long before the first coil was ever wound, the foundation had already been laid in Raimund Mundorf’s childhood, shaped by music, curiosity and a fascination for technology. From that spirit grew a company that would become a trusted reference for high-end audio components worldwide – today found in some of the most renowned loudspeaker systems and amplifiers across the globe.

1985

- In-house production begins – perfection in coil design

- Air-core coils from round and flat wire, 0.12–12 mm²

- FERON transformer core: high-load capacity >1 kW; highly permeable for tight bass response

- The Zero-Ohm Coil – exceptionally low RDC enables precise, controlled bass, rare even in active systems

- “Macro/Micro-Microphonic” theorem applied for the first time in vacuum impragnation technology

- Aronit replaces ferrite – a new core material, extremely stable and with minimal hysteresis distortion, ideal for low-level signals

Learn more

1990s

- International success with premium capacitors: MCap, MCap Supreme, MCap Supreme Silver-Oil

- Expanded production of custom winding technologies

• Delivery of high-performance components for car hi-fi: HeadCap 0.5–1.5 F, long-term stable power supplies up to 13.8 V/400 A

Learn more

2000s

- MCap Supreme Silver-Gold-Oil becomes a global bestseller; Mundorf becomes a trusted industry partner

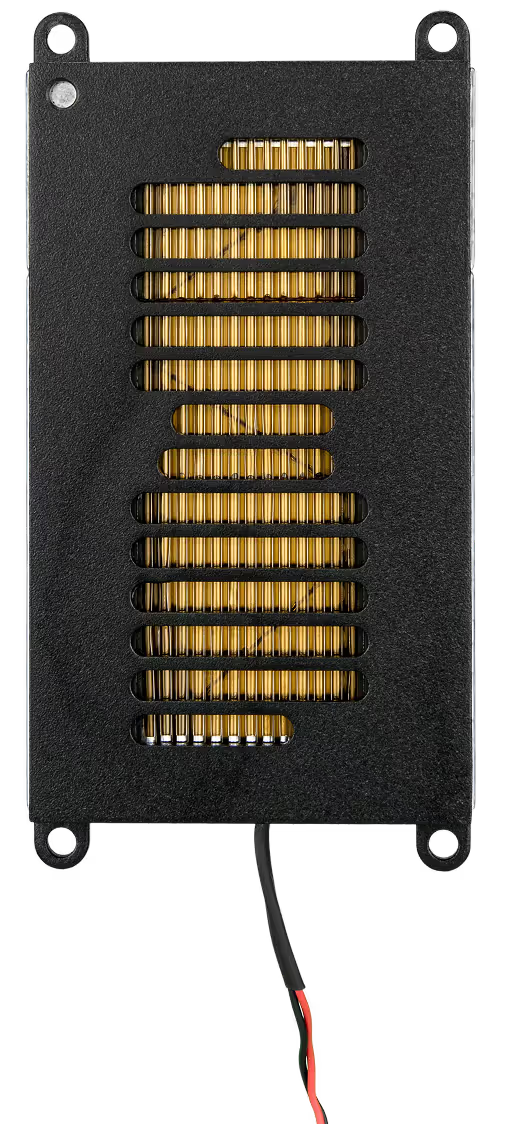

- Holographic Sound Devices – entry into patented AMT High-Frequency Driver

- Technology (AMT 2330/40, AMT 2530, AMT 2930)

First Pro AMT units: AMT U56, AMT 576 (membrane 576×27 mm)

Learn more

2010s

- Product portfolio expands to the full 360° playback chain – new MCap EVO capacitors, precision resistors, terminals, cables and wires

- AMT technology proves itself worldwide in home, cinema, car and pro audio – from private studios to live events, including the Royal Albert Hall in London. For demanding use: instruments and entire orchestras must be amplified neutrally, distortion-free and effortlessly, even at high volumes.

- Presence along the entire playback chain: from studio to home, car and stage – source → electronics/crossovers → loudspeakers. Mundorf AMT tweeters and precision components accompany every step.

Learn more

2020s

- Development of patented Angelique® alloys for applications across the full playback chain

- Introduction of the first Angelique-based products

- Macro/Micro-Microphonic Theorem refined as the physical foundation for holistic optimization of audio components

Learn more

From 2026 onwards

- New Angelique®-based products

- Expanded production and R&D capacities

- Successive website relaunch

- Overhaul and expansion of existing product portfolio

- Comprehensive relaunch of the Pro-AMT line

Learn more

Inside Every Note – The Complete Range of Audio Components

What began with coils has evolved into a complete portfolio of high-quality components for nearly every audio application. Whether in the studio, on stage, in the car, or at home – wherever music unfolds its power, our capacitors, coils, AMT tweeters, resistors, wires and more contribute to a moving sound experience.

True Music Technologies

Every music signal passes through a signal chain in which physical processes can shape or distort its character. Our goal is to free this chain from sound-altering influences and achieve maximum signal fidelity and fatigue-free listening pleasure – an effect perceptible even to untrained listeners. At the center of this are three fields where decisive interactions occur: macro-microphony, micro-microphony, and electrical parameters. Understanding and controlling them is at the heart of our True Music Technologies.

Movement as a source of distortion

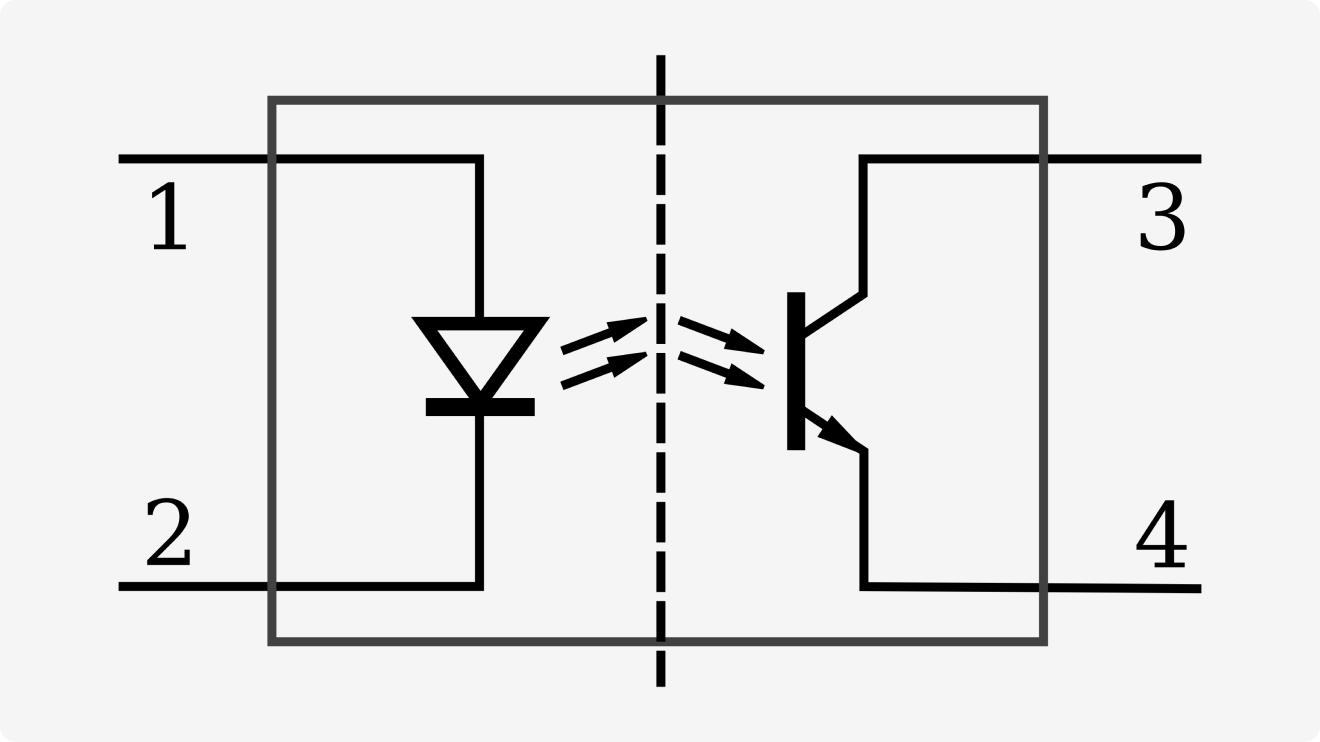

Macro-Microphony

In coils, capacitors, and partly in wire-wound resistors, current flows through tightly wound conductors that interact magnetically and electrically. This creates forces that set the windings of wires or foils into vibration. On one hand, this leads to loss of energy for membrane acceleration and reduces the music’s definition, attack, and microdynamics. On the other, it causes macro-microphonic feedback that can distort the audio signal and superimpose it with noise, ringing, and other subtle artifacts. As a result, the instrument’s character and spatial information can be lost.

Through targeted design measures, we eliminate macro-microphonic effects and preserve the full dynamics, detail, and precision of the music.

The physics within

Micro-Microphony

Micro-microphony examines minute, material-specific effects that occur directly in the conductor or dielectric. Material-specific vibrations of the crystal lattice (phonons), electron scattering at grain boundaries, and local resonances within the structure subtly modulate the signal – often perceptibly affecting the sound.

Micro-microphony cannot be entirely avoided – but it can be damped and controlled. Precisely tailored alloy compositions and accurate control of temperature treatment, pre- and post-processing actively shape each conductor’s resonance behavior, ensuring maximum purity and stability of the signal.

Precise control of electrical characteristics

Electrical parameters

Electrical parameters such as capacitance, inductance, impedance, or dissipation factor describe the basic properties of a component. Yet its sonic behavior depends on how these factors interact. Real components do not exhibit constant behavior: capacitance and ESR vary with frequency, temperature, and voltage. Dielectric losses, saturation effects, and nonlinear transitions shape the dynamics.

We develop and test every component across the full relevant frequency range, ensuring that electrical stability, low losses, and musical coherence remain perfectly balanced.

Why the crossover region is so sensitive

In the crossover region of a frequency range, both drivers – for example, woofer and tweeter – operate simultaneously. It is precisely this fine interaction of level and phase that determines whether the overall result sounds calm, spatially stable, and natural.

Why micro-microphonic effects remain audible

In reality, “zeros and ones” are not abstract states but voltage or current pulses traveling through conductor paths and cables. Each 1 and 0 is a transition – a steep, high-frequency voltage pulse (for example, from 100 MHz up to the GHz range).

Function in amplifiers and signal processing

In amplifiers and analog signal paths, the same physical effects occur as in the frequency domain — but their impact is directly linked to how voltages, currents, and field strengths dynamically interact.

40 Years of Active Research

“Every smallest detail affects the listening experience.”

From alloy composition to production methods: Raimund Mundorf provides detailed insights into the physics of components and metal lattice structures – and explains why metals can sound different.

The interview was originally recorded in German and is presented here with AI-assisted English voice synchronization.You can find the original German version with English subtitles here.

Our Team

We are a diverse team of passionate audio enthusiasts! Rooted in the DIY and high-end audio scene and grown together with international partners from the audio industry, we work every day on components that make the experience of music more vivid, more authentic, and more moving.

We’re happy to advise you

Whether you need the ideal components, technical know-how, or custom solutions – together we’ll find the best answer for your application.